Chemical additive weighing and filling machine

Chemical additive weighing and filling machine

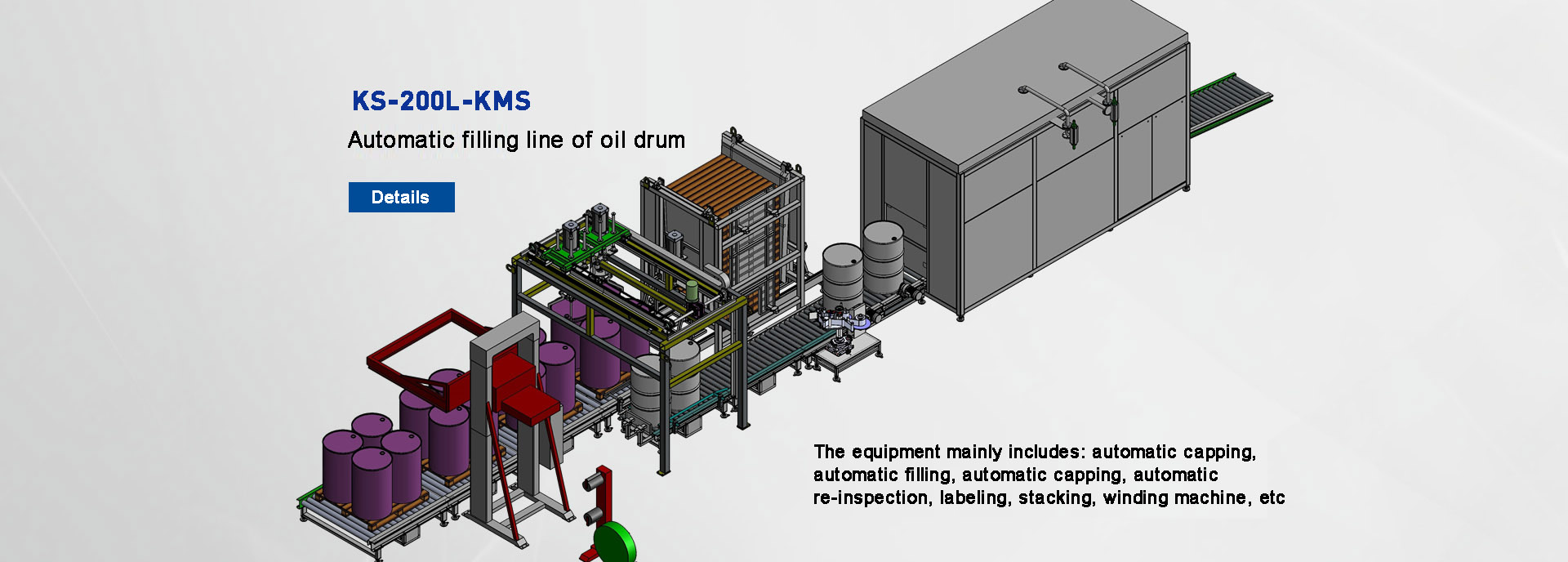

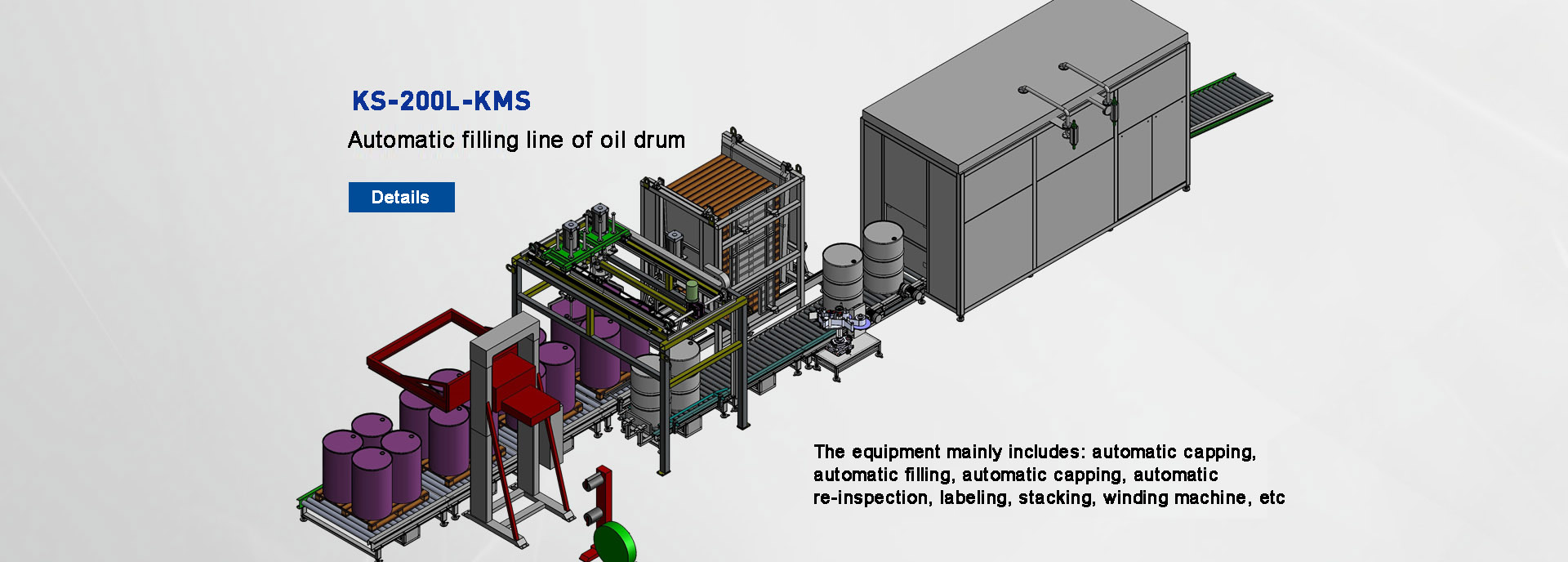

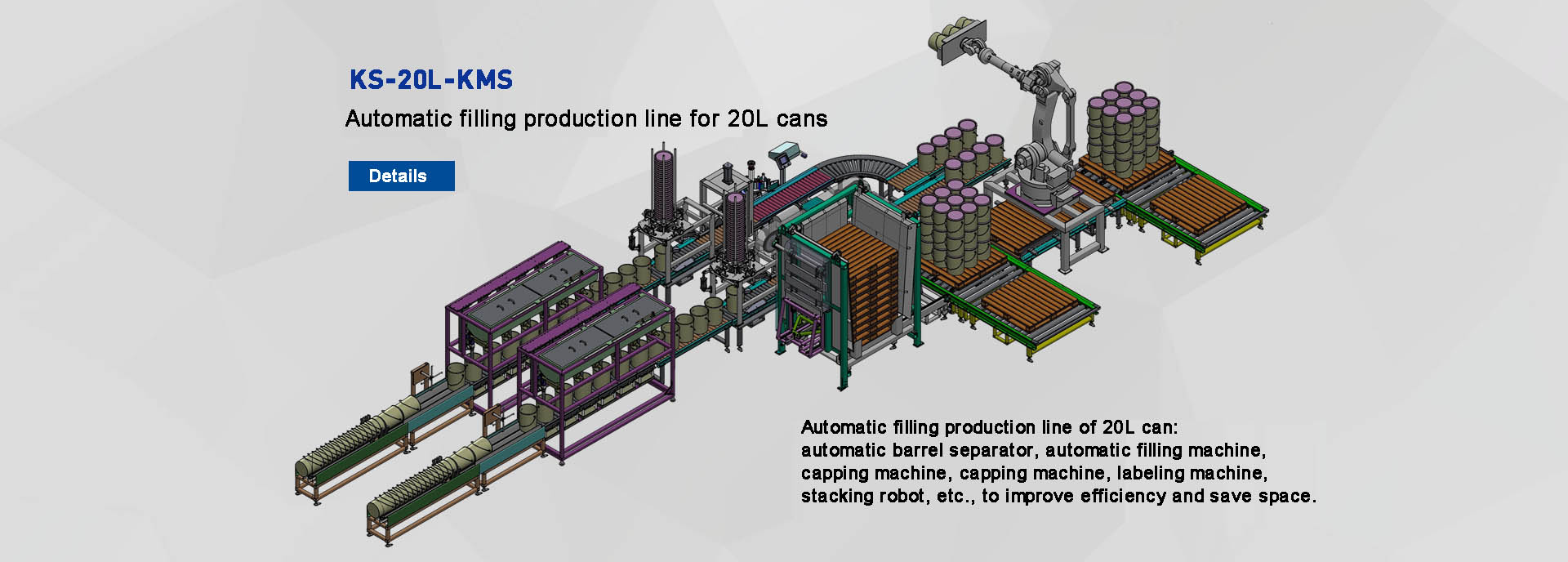

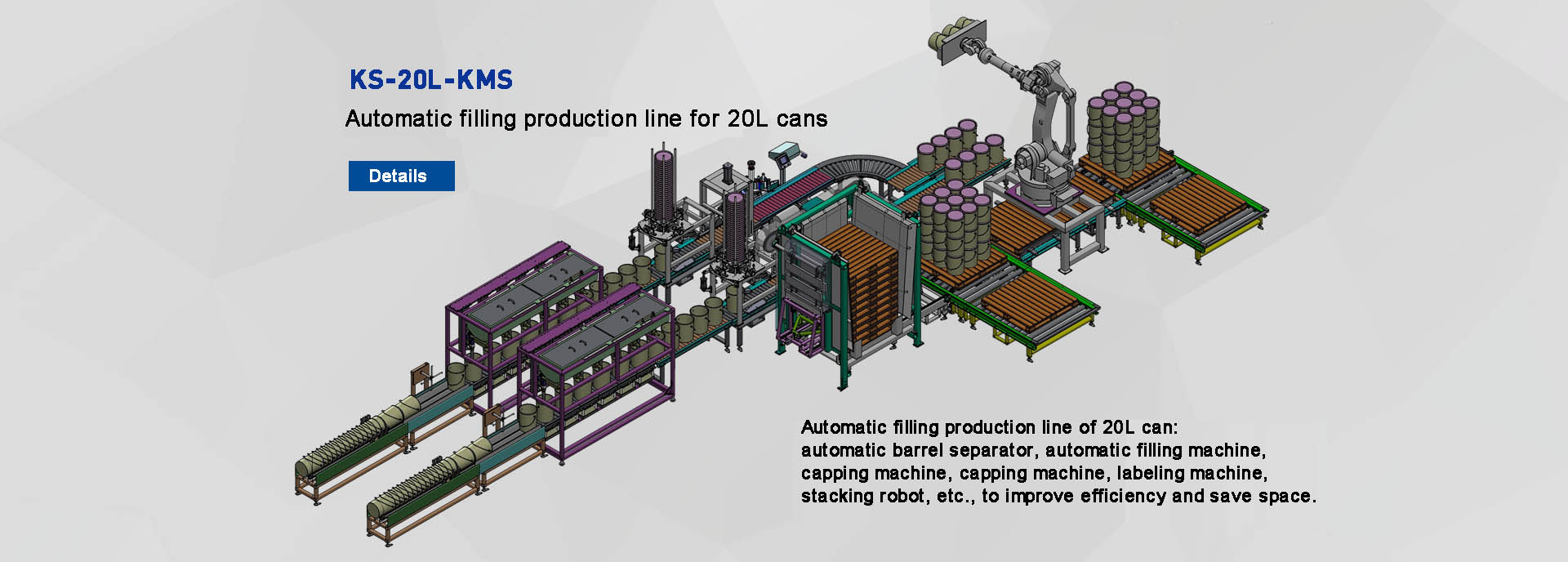

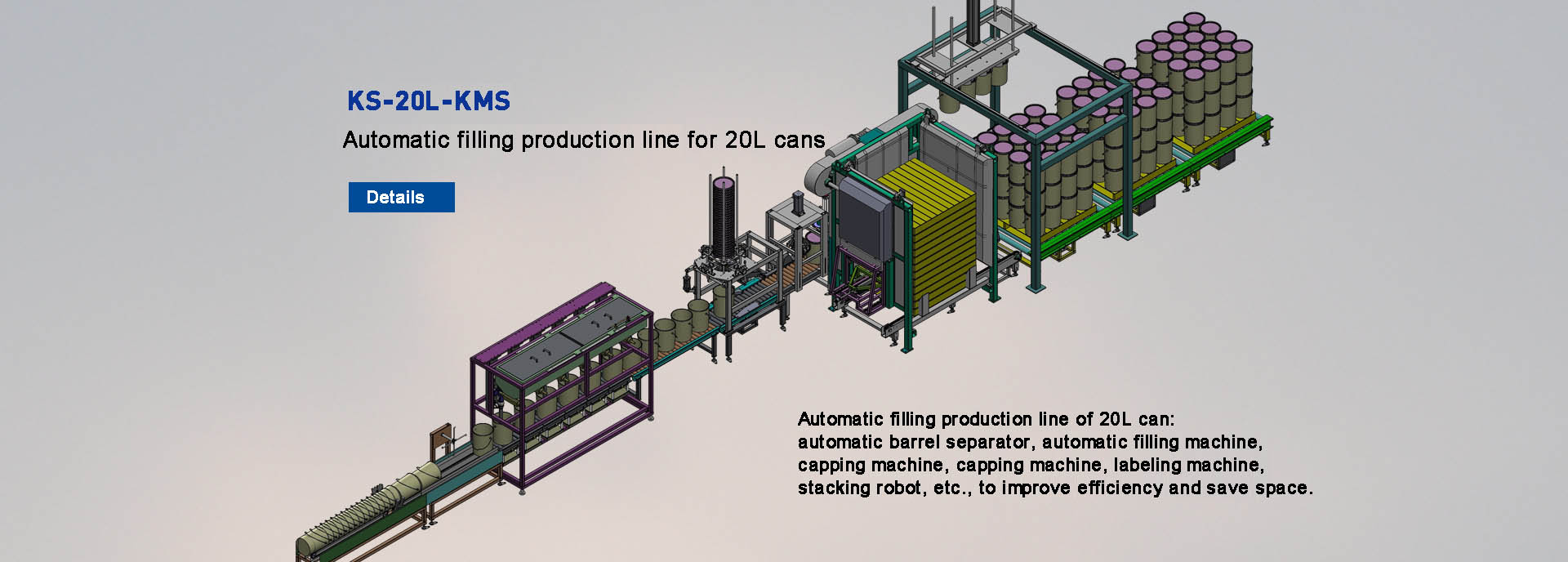

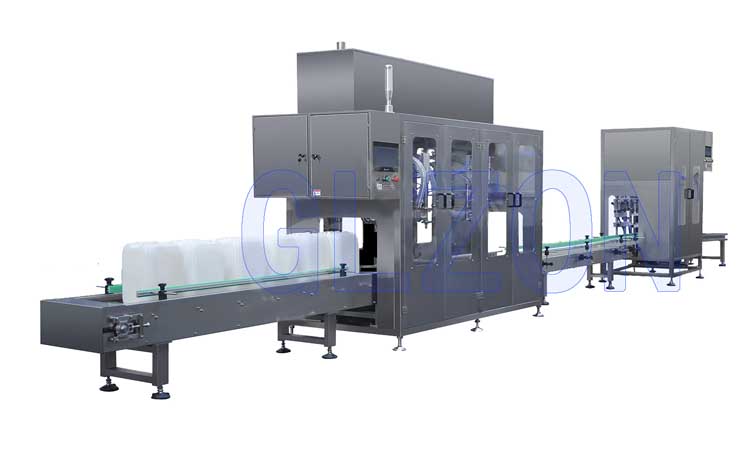

Liquid filling machine is a highly automated packaging equipment, whose main function is to automatically fill liquid materials into the preset weight. The liquid filling machine can effectively avoid material overflow during the filling process and effectively prevent the material itself from polluting the environment, thus providing effective labor protection for operators. The system is stable and reliable, easy to operate and accurate to fill. The filling machine is mainly composed of filling gun device, PLC system control part, weighing system, filling rack, conveying equipment, etc.

System features:

◆ The system adopts programmable PLC controller and Chinese guide operation, with reliable performance;

◆ Automatic conveying, automatic positioning, automatic filling, automatic capping and screwing;

◆ The whole process of filling gun is made to prevent dripping and splashing; Quick connector, easy to disassemble and clean;

◆ The system target value is freely set, and the filling gun height is adjustable, which is suitable for rapid filling of various specifications of packaging barrels;

◆ Equipped with large and small ball valve groups and double-stage filling guns, large, medium, small and micro four-stage filling design, accurate and stable filling;

◆ No filling is allowed without bucket on the weighing platform, and differential pressure type zero time difference bucket collision protection;

◆ Automatic selection of two filling methods: net weight/gross weight (automatic peeling of each barrel);

◆ One-click operation, easy to use; Multi-window display of filling quantity, barrels, cumulative quantity and other information;

◆ There is signal indicator light for instant display and automatic alarm for out-of-tolerance;

◆ Good stability, reduce loss, save cost, improve operation efficiency and reduce manual operation pressure.